ReVolt Brings Clean Energy Innovation to Hollywood

2025-09-10 14:42:46 1494

Charging innovator leverages power modules and renewable energy to significantly reduce carbon emissions in film production

Star power may drive Hollywood's global buzz, but the true force behind massive box office returns remains largely unseen. Currently, most production companies still rely on noisy, environmentally harmful gasoline and diesel generators to power their sets. However, as production sites expand in scale and professional filming electronics grow increasingly complex, energy demands continue to rise, making carbon dioxide emissions an increasingly critical issue.

Figure. 1

Figure 1 ReVolt Holdings, Inc. (ReVolt) has introduced a more advanced solution for powering film sets and studio locations, delivering clean, mobile, and uninterrupted electricity. The ReVolt system operates quietly, efficiently, and with zero carbon emissions, covering all power needs—from cameras, audio equipment, and lighting to special effects rigs and on-site camp facilities.

ReVolt Holdings, Inc. (ReVolt) has introduced an advanced solution for powering film sets and studio locations, delivering clean, mobile, and uninterrupted electricity. The ReVolt system operates quietly, efficiently, and with zero carbon emissions, comprehensively covering all power requirements—from cameras, audio equipment, and lighting to special effects rigs and on-site camp facilities. Founded in 2020, this startup has rapidly gained industry recognition. It has partnered with multiple production companies including Amazon MGM Pictures, Apple Studios, Sony Pictures, Warner Bros. Discovery, and its subsidiary HBO to provide clean power for their filming locations.

ReVolt's Clean Power System Offers a Noise-Free Alternative to Traditional Diesel Generators

Before founding ReVolt, J.D. Schwalm gained extensive experience in special effects technology development at his first company, Innovation Workshop. Now as ReVolt's CEO, he has become an industry leader advocating for cleaner, more efficient power to replace diesel generators.

A 10-kilowatt diesel generator produces approximately 75 decibels of noise—equivalent to a leaf blower—and emits as much carbon dioxide in 12 hours as a gasoline-powered car traveling 225 miles. Due to noise and exhaust emissions, diesel generators must typically be placed 1,000 feet or more away from film sets, requiring thousands of feet of expensive, cumbersome cabling.

Additionally, diesel generators produce “dirty electricity,” necessitating extra filtering equipment to power precision digital lighting and motion control devices. In contrast, the ReVolt charging system delivers pure sine wave power, ensuring clean, stable electricity with near-silent operation—producing only a sound akin to a computer fan.

Figure. 2

Figure 2 ReVolt offers a growing portfolio of portable generator units, all providing uninterrupted power. The currently available WeVolt (shown) is the smallest product delivering industrial-grade three-phase power.

ReVolt Overcomes Continuous Power Supply Technology Bottlenecks, Secures Multiple Patents

ReVolt's inception stemmed from Schwalm's insight into an industry pain point: how to provide stable, uninterrupted power to complex and variable electrical loads across an entire film production site with limited battery capacity.

He stated: "Diesel generators can supply power for extended periods as long as fuel is continuously added. At the time, no battery system globally could achieve this. That's when ReVolt emerged, introducing a battery generator system capable of operating while charging."

ReVolt applies its uninterruptible power technology to an expanding portable fleet. The smallest model, WeVolt, delivers 17.5 kWh capacity and 14 kW output—equivalent to a small home generator. The 8,500-pound Mule model delivers 210 kWh of energy and 120 kW of output power, supporting multiple voltage connections including 480V, 208V, 240V, and 110V. In 2024, Schwalm and his team secured two patents for their continuous battery power design, with three additional patents pending.

Vicor high-power-density modules ensure system reliability, high performance, and efficiency

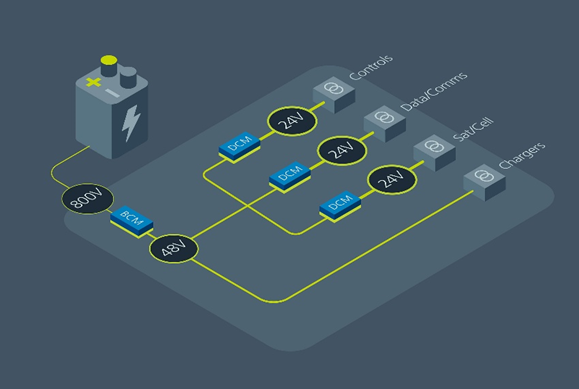

To maintain stable system voltage, ReVolt employs Vicor's BCM® bus converters, DCM™ DC-DC converters, and the newly introduced PRM™ voltage regulators.

Figure 3

The BCM4414 converts and isolates 800V voltage to a 35A 48V bus, while the DCM3414 draws power from this bus and regulates it for 24V loads. The BCM4414 also functions as a battery simulator, reducing the need for bulky 48V batteries.

The BCM4414 converts and isolates an 800V voltage into a 48V bus at 35A, while the DCM3414 draws power from this bus and regulates it for 24V loads. The BCM4414 achieves a power density of 770W/in³ in a compact 4.35 x 1.4 x 0.37-inch package. It also functions as a battery simulator, reducing the need for bulky traditional 48V batteries. The PRM is a non-isolated buck-boost DC-DC regulator capable of converting 48V to multiple output voltages, achieving power density exceeding 2kW/in³ with efficiency up to 96%.

Schwalm notes: “A single Vicor module delivers performance previously requiring six to eight components.”

Looking Ahead: Powering More Scenarios from Disaster Relief to Healthcare Settings

Today, the demand for portable clean energy has never been more urgent. While gradually redefining power delivery for the film industry, ReVolt is actively expanding into broader new application areas—from serving disaster-stricken regions to providing clean power for construction sites and large-scale events.

With the rise of electric vehicles and society's growing demand for greener, more sustainable energy, ReVolt is deepening its collaboration with Vicor—a leader in modular power solutions—to lay the foundation for a more environmentally conscious future.