ams OSRAM Launches New Laser Diode for Next-Generation Automotive Lidar Applications

2025-11-14 15:33:18 1451

Shanghai, China, 14 November 2025 – ams OSRAM, a global leader in lighting and sensing innovation, today announced the launch of a new five-junction edge-emitting laser diode, driving lidar system performance to new heights. The realisation of autonomous driving relies on sensor technology capable of delivering precise, reliable, and long-range detection at all times. Lidar systems operate independently of lighting conditions, continuously capturing three-dimensional environmental data to enable real-time safety decisions.

Figure. 1

Compared to previous tri-junction technology, ams OSRAM's new laser diodes achieve a significant increase in peak power while consuming less power. While conventional triple-junction lasers already extend detection range by 50% over standard emitters, the five-junction laser takes this further: its five vertically stacked emitter layers integrated within a single die not only substantially expand detection capabilities but also markedly improve energy efficiency. Furthermore, its low resistance loss reduces heat generation, thereby simplifying thermal management design. This proves a significant advantage within compact automotive architectures.

Tobias Hofmeier, Product Marketing Manager at ams OSRAM, stated: ‘Our five-junction laser diodes empower automotive manufacturers to develop LiDAR solutions that combine robust performance, precise detection, high energy efficiency, and flexible scalability. Their exceptional detection range, outstanding stability, and straightforward integration will be key drivers accelerating the realisation of autonomous driving.’

For lidar system developers, the introduction of the new five-junction laser signifies a qualitative leap in system performance while reducing complexity. Operating at lower currents, it diminishes the requirement for drive electronics. Simultaneously, integrated wavelength stabilisation technology ensures consistent measurement results, even under temperature variations or harsh environmental conditions. This provides a reliable, efficient, and scalable core component for next-generation automotive sensor systems. The new five-junction laser is supplied in bare die form. This solution enables system developers to achieve more flexible designs while saving valuable space, facilitating the creation of more compact and efficient lidar modules.

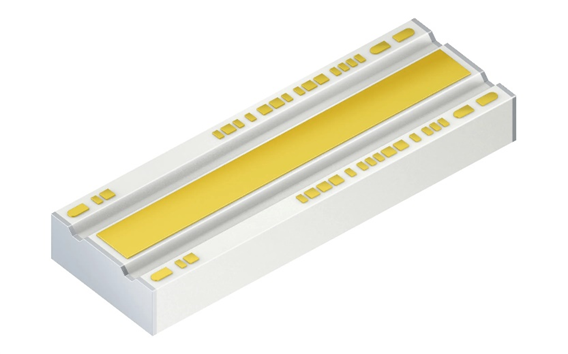

Figure. 2 SPL DP91A_5 Product Image

For automotive manufacturers, the strategic value and industry impact of ams OSRAM's new five-junction edge-emitting laser is profound. The device enables extended detection ranges, allowing systems to identify targets earlier – whether pedestrians crossing roads at night or disabled vehicles on bends. Simultaneously, its enhanced detection accuracy improves target classification precision, effectively reducing false alarms. In terms of energy efficiency, the new device's improvements permit more compact system designs, optimised costs, and simplified thermal management solutions. Moreover, its compact chip size enables rapid, seamless integration onto existing platforms, significantly shortening development cycles to accelerate mass production.

LiDAR technology is no longer confined to premium vehicles. Its applications are rapidly expanding—from autonomous taxis navigating urban environments and automated delivery vehicles to motorway-grade Advanced Driver Assistance Systems (ADAS). Enhanced detection range and precision not only optimise target detection and classification capabilities but also empower automotive manufacturers to raise the upper limits of autonomous driving speeds. This unlocks new possibilities for motorway driving and advanced driver assistance systems while ensuring safety and system reliability remain unaffected.

ams OSRAM's new five-junction laser will be available globally from early 2026. For further product information, please visit the official website.