Pushing the limits of performance: GaN enables high-frequency motor drives

2025-07-29 11:27:18 1032

Complex new technology applications such as humanoid robots place stringent demands on motor drives: the drives must provide precise control capabilities to ensure that speed, torque and efficiency remain constant. In recent years, these motor systems have developed rapidly, which is inseparable from technological advances and material innovations in the electronic power industry - many applications are transitioning from traditional silicon-based devices to advanced gallium nitride (GaN) solutions. GaN technology has unlocked new potential for high-frequency operation, bringing unparalleled advantages to motor drives. This article will explore the practical value of high-frequency motor drives and the unique capabilities of GaN technology, which enable it to meet complex requirements for motor drive performance.

What does high frequency do for motor drives?

Motor drive systems that can perform high-frequency operation can achieve smoother and more efficient operation, helping to make the application more compact in design. Silicon-based device systems have limitations in switching speed, and the operating frequency is usually limited to less than 40 kHz. GaN transistors can break through these limitations and increase the switching frequency to more than 100 kHz.

Key Benefits:

1. Reduced Total Harmonic Distortion (THD): High-frequency switching reduces harmonic losses and improves the overall efficiency of the motor. Lower THD also results in quieter operation, making it ideal for applications that require noise reduction, such as robotics and industrial automation.

2. Compact filter design: High-frequency operation reduces the size of input and output filters. Unlike traditional systems that require large electrolytic capacitors, high-frequency drivers can use ceramic capacitors, reducing size, weight, and cost, and improving reliability.

3. Minimized dead time: High-frequency switching supported by GaN devices reduces the dead time between switching events and avoids common conduction, thereby reducing torque ripple and improving motor performance.

4. Improved efficiency: High-frequency operation effectively reduces motor losses. This is critical for battery-powered applications because efficiency directly affects device endurance and performance.

5. Better dynamic response: Higher switching frequencies enable faster response of motor speed and torque control, resulting in better performance in dynamic applications such as drones, e-bikes, and robots.

Why does motor drive require GaN solutions?

As motor drive applications continue to push the limits of performance, GaN technology has become the undisputed solution. Conventional silicon-based MOSFETs cannot match GaN transistors in terms of high-speed switching, low losses, and compact size.

Advantages of GaN in motor drives

1. Low switching losses: GaN has significantly lower switching losses than silicon-based devices, allowing it to maintain extremely high efficiency under high-frequency conditions, thereby reducing heat generation and improving reliability in motor drive systems.

2. High power density: GaN devices are smaller and more powerful, enabling miniaturization of inverters. This is critical for space-constrained applications such as drones, humanoid robots, and personal mobile devices.

3. No reverse recovery loss: In hard-switching topologies, silicon-based devices have reverse recovery losses, while GaN transistors completely eliminate this problem, thereby improving overall efficiency and enhancing system robustness.

Challenges and breakthroughs in high-frequency motor drive design

Thermal management

High-frequency operation generates heat, which may affect system reliability. With the excellent thermal conductivity and low switching loss characteristics of GaN, the heat dissipation problem can be solved. In addition, the optimized PCB layout (for example, with efficient heat dissipation paths and thermal vias) can further improve the heat dissipation performance.

Electromagnetic Interference (EMI)

High-frequency switching increases electromagnetic radiation. Integrating the inverter directly into the motor can shorten the distance between high-frequency components and further reduce interference.

What are the application scenarios of high-frequency motor drives?

Figure. 1

A small motor that can be used for robot joints with a diameter of no more than 9 cm.

Industrial and service robots

Industrial and service robots rely on efficient and precise motor drives to perform complex tasks. These robots are equipped with multiple brushless DC (BLDC) motors, each of which requires a separate inverter. GaN-based motor drives can be easily integrated into the limited space at the joints with a smaller size and maintain high efficiency, making them an ideal choice for robot design. In addition, high-frequency operation ensures smooth torque output and reduces heat generation, which is an advantage for robots that work continuously.

Drones

Unmanned aerial vehicles (UAVs) require lightweight, high-efficiency motor drives to extend range and increase load capacity. The high-frequency operation characteristics of GaN inverters can significantly improve motor efficiency. The advantages of GaN-based systems in weight reduction and miniaturization are particularly important for such "gram-by-gram" aviation applications.

Tools and Equipment

Motor drives using GaN can provide higher efficiency and better motor speed and torque control to improve performance, suitable for equipment such as forklifts and power tools. GaN devices can handle higher currents while reducing heat losses, which makes them particularly suitable for harsh environments. GaN's high-frequency operation can reduce noise and vibration, improving user comfort and safety.

Electric Mobility

In modern electric bicycles, GaN inverters play a key role, providing higher efficiency and compact design. These drives operate at higher pulse width modulation (PWM) frequencies, reducing input and output ripple, eliminating the need for bulky LC filters. The improved efficiency ensures longer battery life, while the reduced size and weight allow them to be seamlessly integrated with the electric bicycle's motor.

Case Study: GaN Technology in High-Performance Robotics

Today’s humanoid robots contain dozens of brushless DC motors for locomotion, a classic use case for GaN technology. These robots require compact, lightweight, and efficient motor drives to mimic human-like mobility and achieve extended runtimes, while brushless DC motors drive the movements of the robot’s joints, limbs, and other mechanical parts. The motors that power small joints only need to support low currents, while more complex parts such as hips and legs require up to 150 amps. GaN inverters provide high-frequency operation to ensure smooth, precise control of each motor for realistic movements. In addition, the use of GaN devices allows for integrated designs, reducing overall weight and improving efficiency, allowing humanoid robots to perform complex tasks with greater precision.

The Future of GaN in Motor Drives

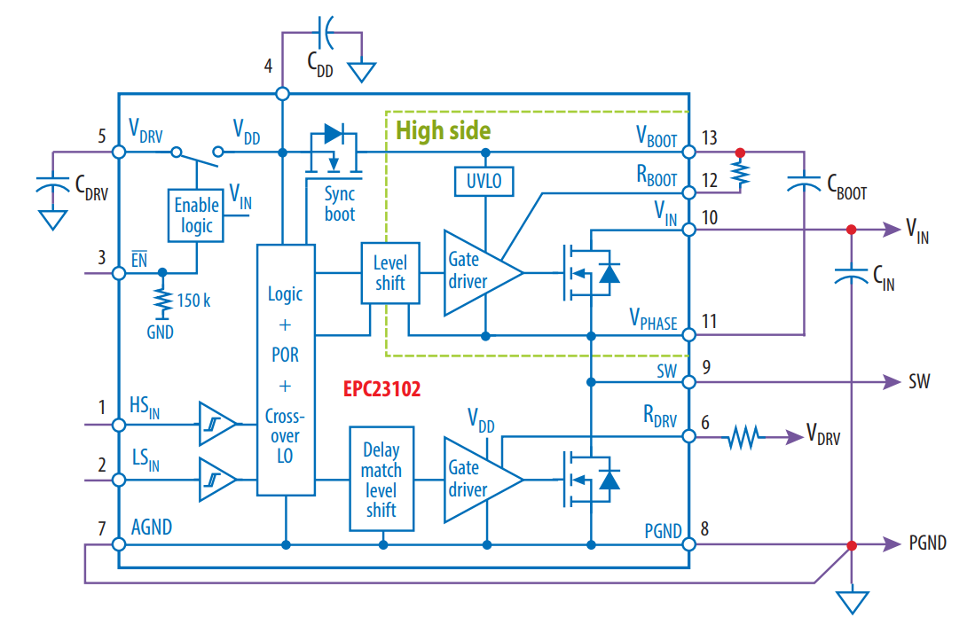

As robotics, electric vehicles, and industrial automation advance, GaN technology will play an increasingly important role in the future of power electronics. These popular applications require motor drives that are more efficient and miniaturized, and GaN is precisely what it can do. Innovations in GaN device design, such as integrated GaN power ICs like the EPC23102 and EPC23104, will further simplify high-frequency motor drive designs, reducing design complexity and cost. Figure 2 shows a block diagram of the EPC23102 ePower Stage IC.

Figure. 2 Block Diagram of the EPC23102 IC

High-frequency motor drives are the new frontier in motor applications, enabling superior efficiency, performance, and compactness. GaN technology is perfectly suited to the design challenges of high-frequency motor drives. From drones and humanoid robots to industrial machinery, GaN-based motor drive designs are revolutionizing motor control technology, creating quieter, more efficient, and highly reliable systems. As the demand for high-performance motor drives continues to grow, GaN technology will continue to lead the next generation of innovations in e-mobility, automation, and more.